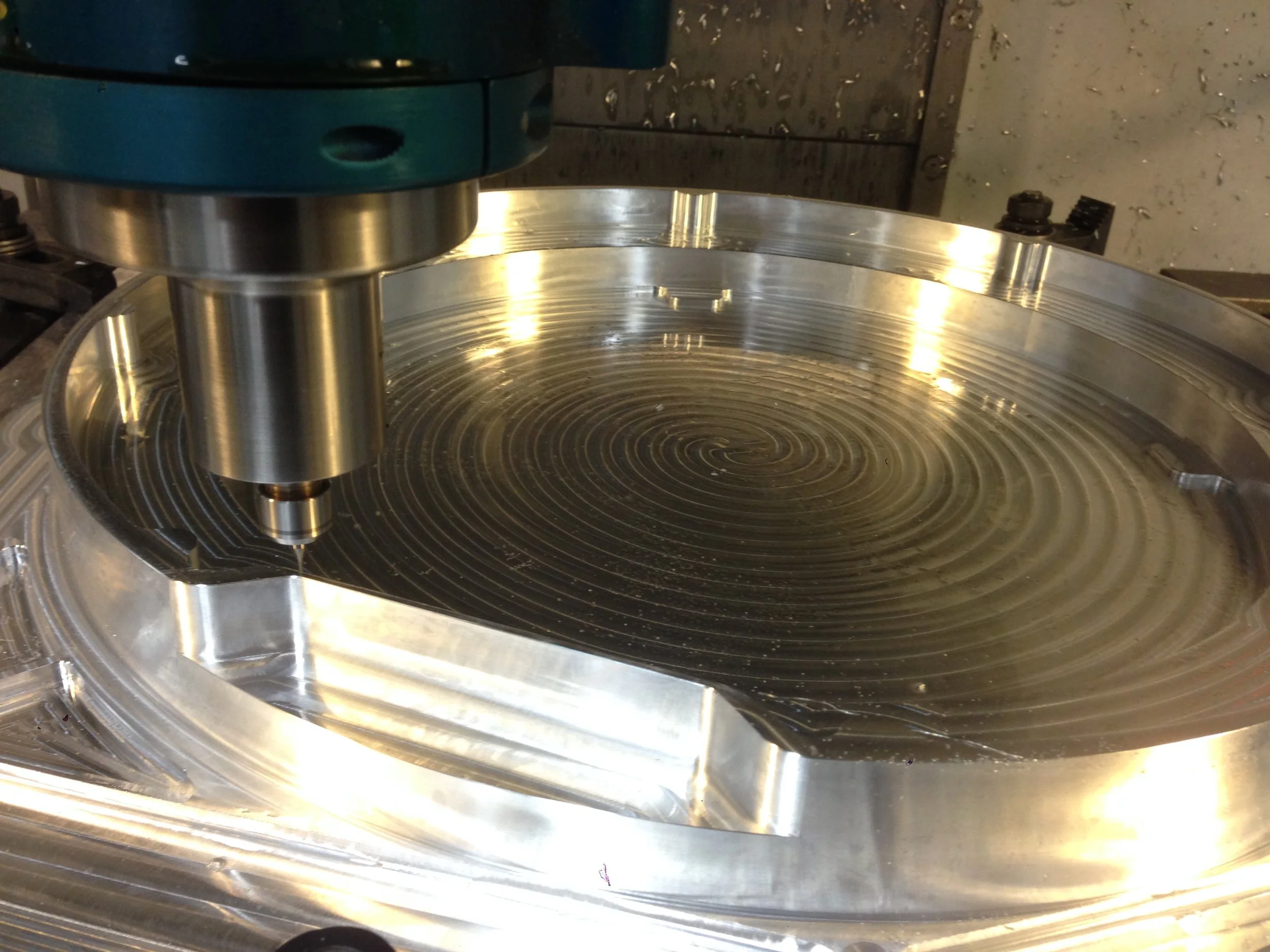

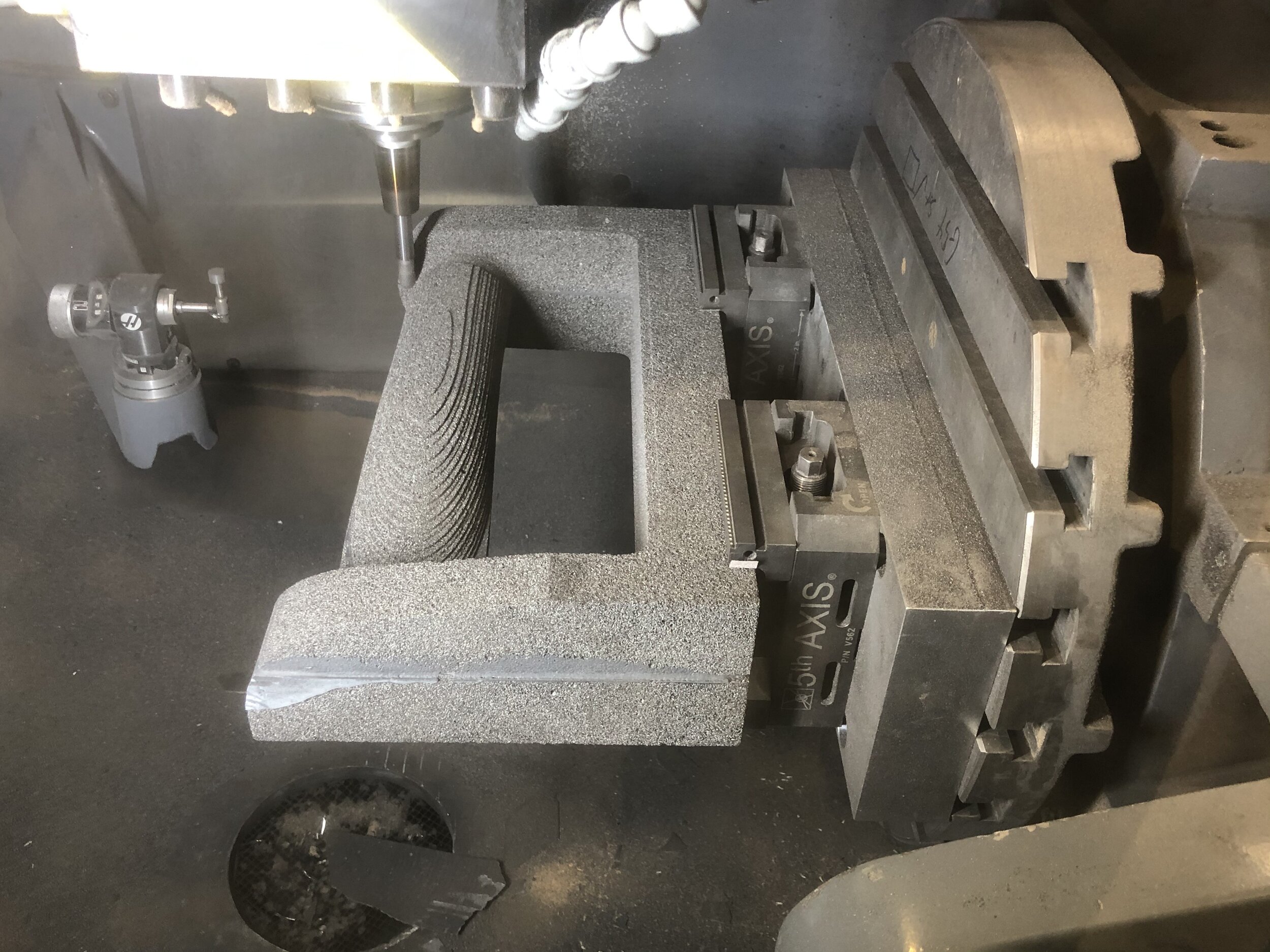

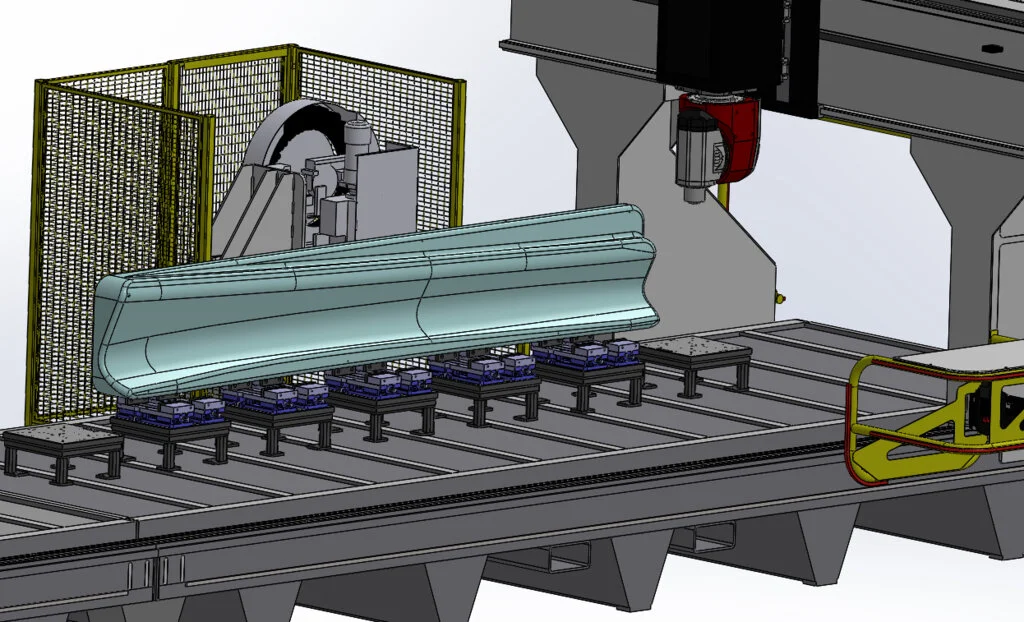

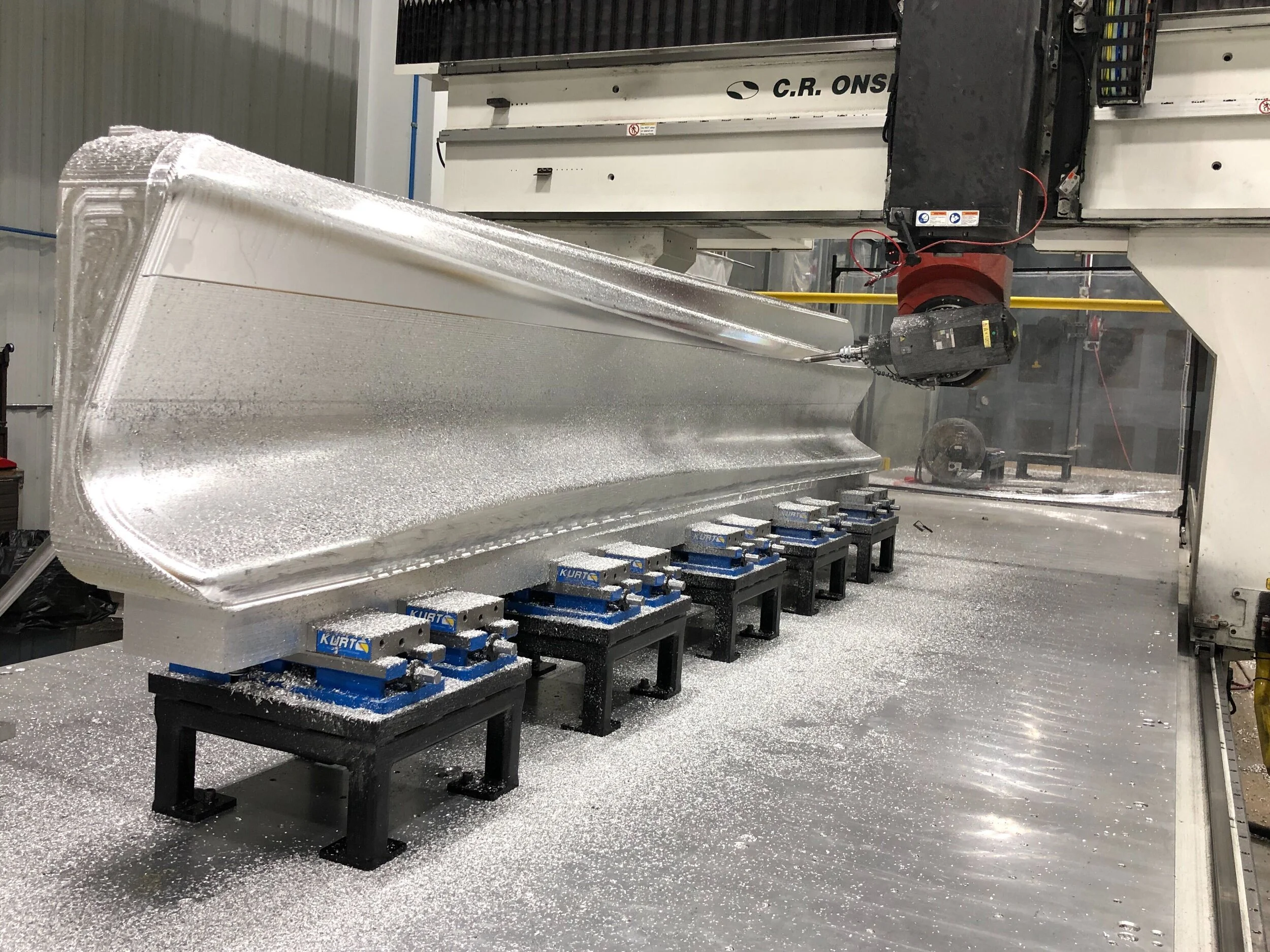

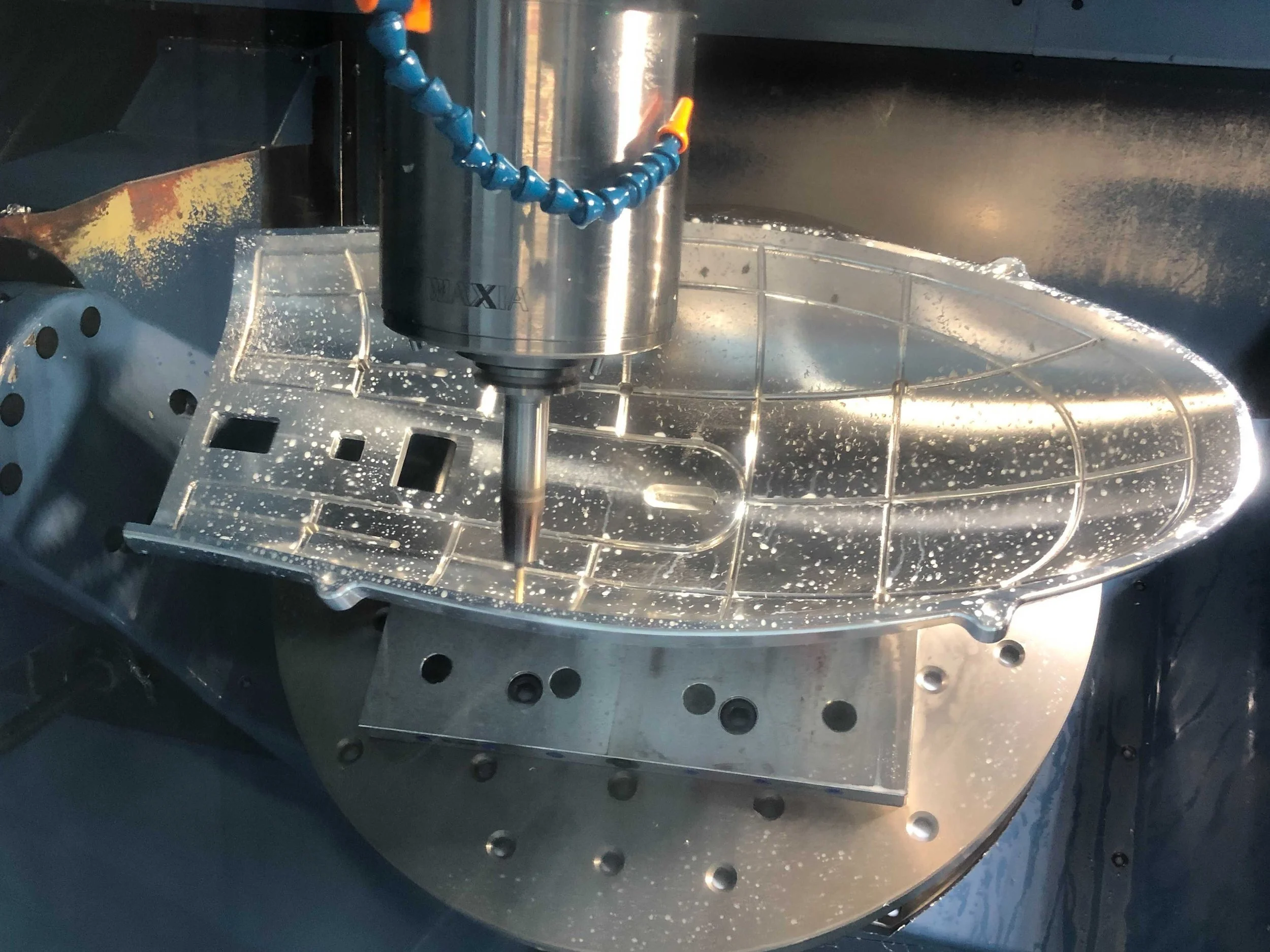

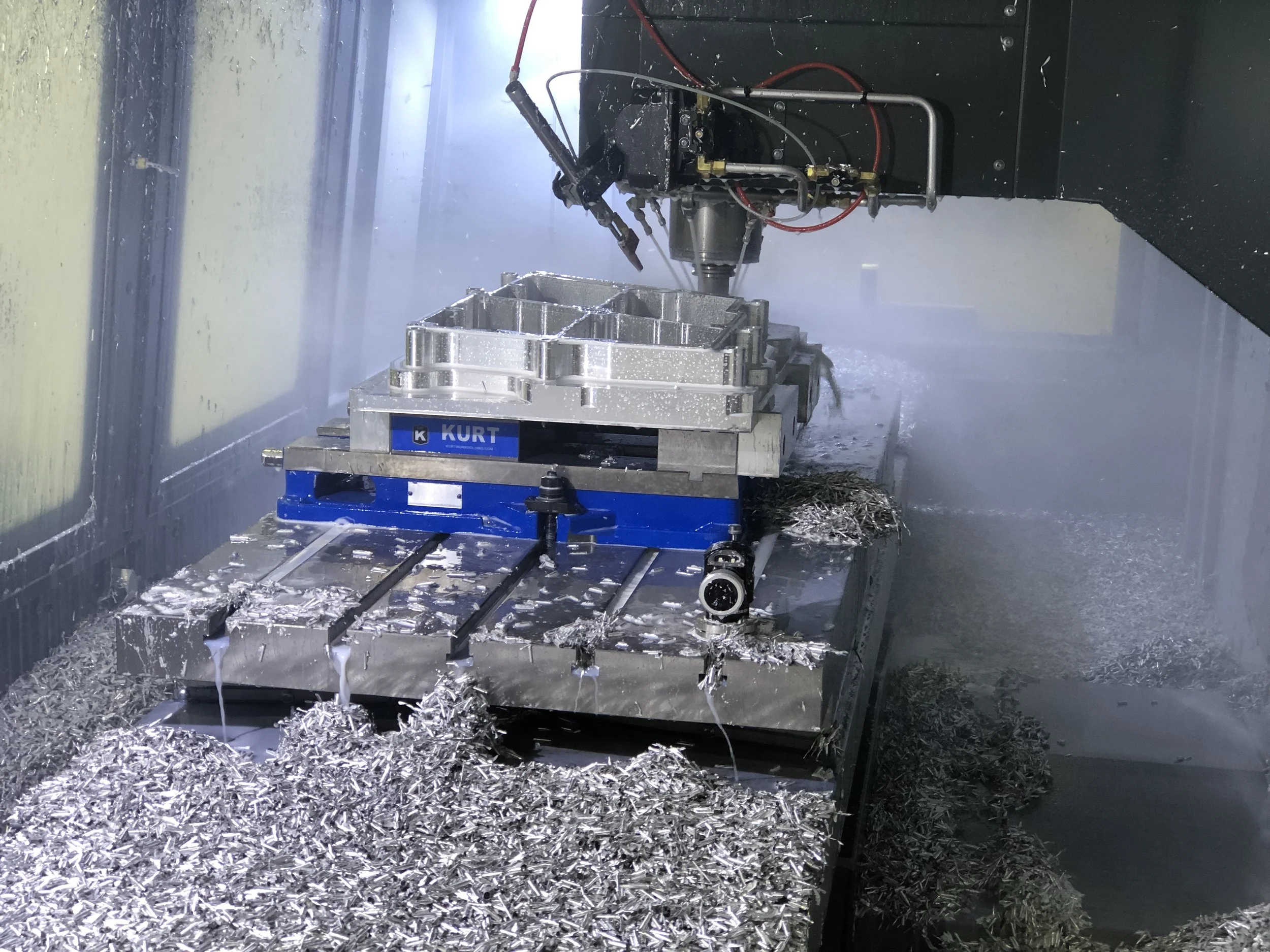

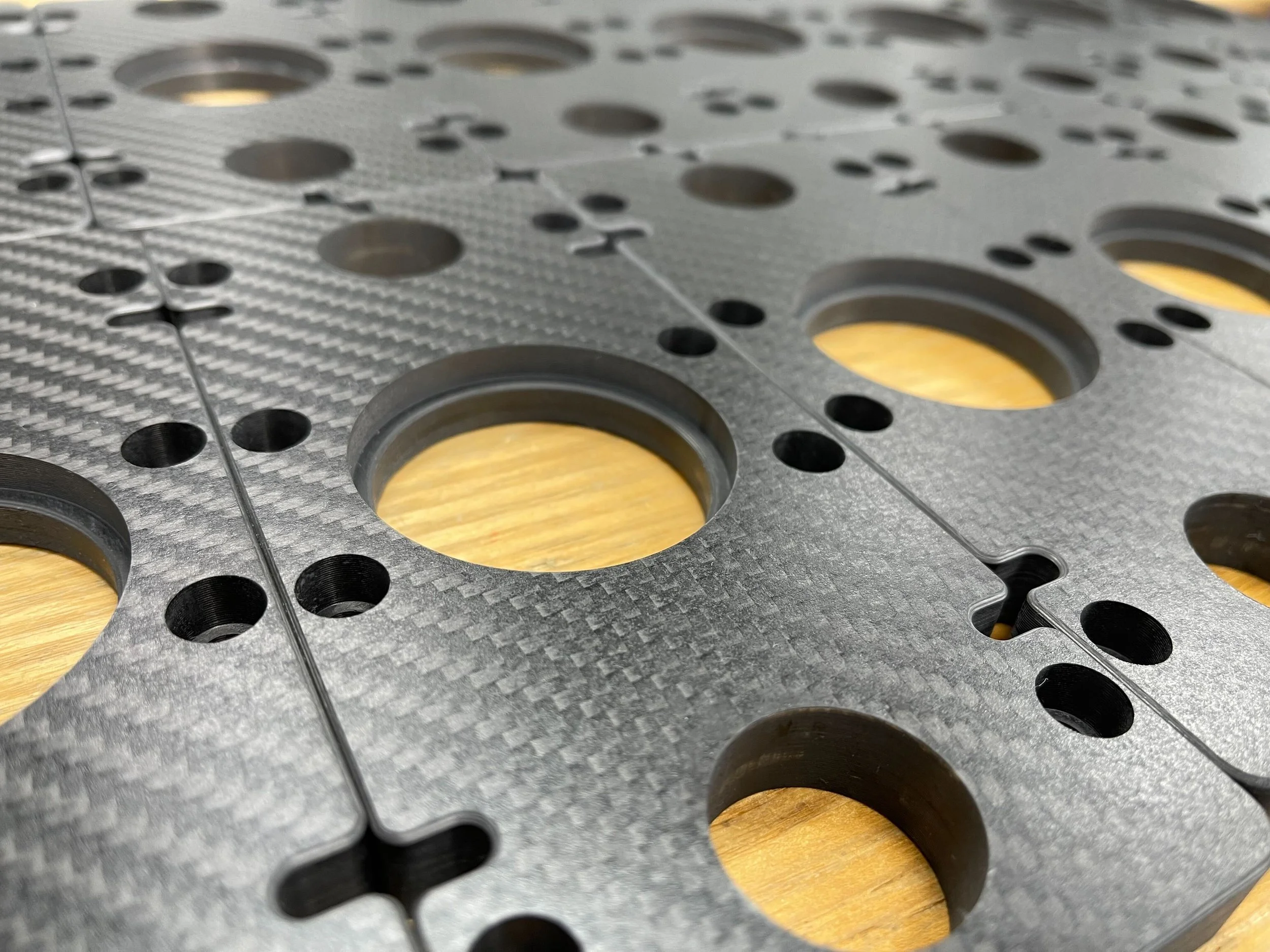

Machine Shop Capabilities

View fullsize

![]()

View fullsize

![]()

View fullsize

![]()

View fullsize

![]()

View fullsize

![]()